Haɗaɗɗen injin gano iskar gas mai ɗaukuwa

Tsarin tsari

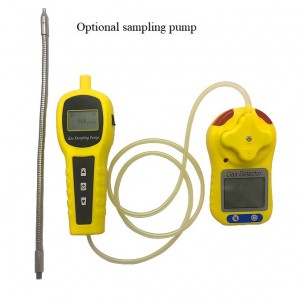

1. Tebura1 Jerin Abubuwan Abubuwan Haɗaɗɗen Gas mai ɗaukar hoto

|  |

| Haɗaɗɗen Gas Gas mai ɗaukuwa | Caja na USB |

|  |

| Takaddun shaida | Umarni |

Da fatan za a duba kayan nan da nan bayan an kwashe kaya. Daidaitaccen na'urorin haɗi dole ne. Zabin shine za'a iya zaɓa bisa ga bukatun ku. Idan ba ku da buƙatar daidaitawa, saita sigogin ƙararrawa, ko karanta rikodin ƙararrawa, kar ku sayi na'urorin haɗi na zaɓi.

Sigar tsarin

Lokacin Caji: kimanin awa 3 ~ 6 hours

Yin cajin wutar lantarki: DC5V

Lokacin Sabis: kamar awanni 12 (sai lokacin ƙararrawa)

Gas: iskar oxygen, iskar gas mai ƙonewa, carbon monoxide, hydrogen sulfide. Wasu nau'ikan ana iya sanye su ta hanyar buƙata

Yanayin Aiki: Zazzabi 0 ~ 50 ℃; yanayin zafi <90%

Lokacin Amsa: Oxygen <30S; carbon monoxide <40s; iskar gas mai ƙonewa <20S; hydrogen sulfide <40S (wasu an cire su)

Girman Kayan aiki: L * W * D; 120 * 66 * 30

Ma'aunin Ma'auni sune: a cikin tebur mai zuwa.

Tebur 2 Ma'aunin Ma'auni

| Gas | Sunan gas | Fihirisar fasaha | ||

| Kewayon aunawa | Ƙaddamarwa | Alamar ƙararrawa | ||

| CO | Carbon monoxide | 0-1000pm | 1ppm ku | 50ppm ku |

| H2S | Hydrogen sulfide | 0-200ppm | 1ppm ku | 10ppm ku |

| EX | Gas mai ƙonewa | 0-100% LEL | 1% LEL | 25% LEL |

| O2 | Oxygen | 0-30% vol | 0.1% vol | Ƙananan 18% vol Babban 23% vol |

| H2 | Hydrogen | 0-1000pm | 1ppm ku | 35ppm ku |

| CL2 | Chlorine | 0-20pm | 1ppm ku | 2ppm ku |

| NO | Nitric oxide | 0-250pm | 1ppm ku | 35ppm ku |

| SO2 | Sulfur dioxide | 0-20pm | 1ppm ku | 10ppm ku |

| O3 | Ozone | 0-50pm | 1ppm ku | 2ppm ku |

| NO2 | Nitrogen dioxide | 0-20pm | 1ppm ku | 5ppm ku |

| NH3 | Ammonia | 0-200ppm | 1ppm ku | 35ppm ku |

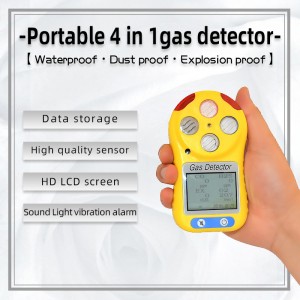

Siffofin samfur

● Ma'anar nunin Sinanci

Gano nau'ikan iskar gas guda huɗu a lokaci guda, ana iya saita nau'in gas gwargwadon buƙatun mai amfani

● Ƙarami da sauƙin ɗauka

● Maɓallai biyu, aiki mai sauƙi

● Tare da ainihin agogo za a iya saita kamar yadda ake buƙata

● LCD na ainihi nuni na iskar gas da matsayi na ƙararrawa

● Daidaitaccen baturin lithium mai caji

● Tare da rawar jiki, fitilu masu walƙiya da sautuna iri uku na yanayin ƙararrawa, ƙararrawar na iya yin shiru da hannu.

● Sauƙaƙe gyarawa ta atomatik (idan babu yanayi mai guba zai iya taya)

● Hanyoyin saka idanu na gas guda biyu, dacewa don amfani

● Ajiye fiye da rikodin ƙararrawa 3,000, ana iya buƙata don duba shi

Mai gano iskar gas na iya nuna nau'ikan iskar gas guda huɗu a lokaci guda ko nau'ikan alamomin lambobi ɗaya na iskar. Fihirisar iskar gas da za a gano ta wuce ko faɗuwa ƙasa da ƙa'idar da aka saita, kayan aikin za su gudanar da jerin ayyukan ƙararrawa ta atomatik, fitillu masu walƙiya, girgiza da sauti.

Mai ganowa yana da maɓalli guda biyu, nuni na LCD da ke hade da na'urorin ƙararrawa (hasken ƙararrawa, buzzer da vibration), kuma ana iya cajin micro USB interface ta micro USB; Bugu da ƙari, za ka iya haɗa kebul na tsawo na serial ta hanyar toshe adaftan (TTL zuwa USB) don sadarwa tare da kwamfuta, daidaitawa, saita sigogin ƙararrawa da karanta tarihin ƙararrawa. Mai ganowa yana da ma'ajin lokaci na gaske don yin rikodin matsayin ƙararrawa na ainihi da lokaci. Takamaiman umarni don Allah koma zuwa bayanin da ke gaba.

2.1 Button aiki

Kayan aiki yana da maɓalli guda biyu, aiki kamar yadda aka nuna a tebur 3:

Table 3 aiki

| Maɓalli | Aiki |

|

| Boot, kashewa, da fatan za a danna maɓallin sama 3S Duba sigogi, da fatan za a danna  Shigar da aikin da aka zaɓa |

| Shiru Shigar da menu kuma tabbatar da ƙimar saita, a lokaci guda, da fatan za a danna maɓallin  button kuma button kuma maballin. maballin.Zaɓin menu  button, danna button, danna maballin don shigar da aikin maballin don shigar da aikin |

Lura: wasu Ayyuka a kasan allon azaman kayan nuni.

Nunawa

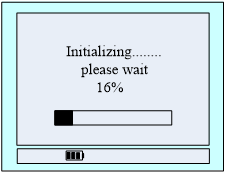

Zai je nunin taya ta dogon danna maɓallin dama a cikin yanayin alamun gas na yau da kullun, wanda aka nuna a FIG.1:

Hoto 1 Nuni Boot

Wannan keɓancewa shine jira don daidaita sigogin kayan aiki. Wurin gungurawa yana nuna lokacin jira, kusan 50s. X% shine jadawali na yanzu. Kusurwar hagu na ƙasa shine lokacin na'urar na yanzu wanda za'a iya saita shi a menu. Ikon yana nuna matsayin ƙararrawa (yana juya zuwa lokacin ƙararrawa). Ikon

yana nuna matsayin ƙararrawa (yana juya zuwa lokacin ƙararrawa). Ikon a dama yana nuna cajin baturi na yanzu.

a dama yana nuna cajin baturi na yanzu.

A ƙasan nunin akwai maɓallai biyu, zaku iya buɗe / rufe mai ganowa, sannan shigar da menu don canza lokacin tsarin. Ayyuka na musamman na iya nufin saitunan menu masu zuwa.

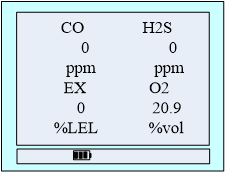

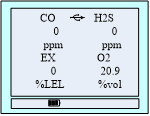

Lokacin da kashi ya juya zuwa 100%, kayan aikin yana shiga cikin nunin gas na 4 mai saka idanu. Hoto na 2:

FIG.2 yana lura da nunin gas 4

Nuna: nau'in gas, maida hankali gas, naúrar, matsayi. Nuna a cikin FIG. 2.

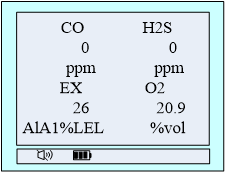

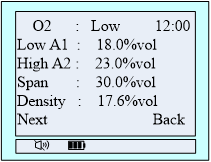

Lokacin da iskar gas ya wuce manufa, nau'in ƙararrawa (carbon monoxide, hydrogen sulfide, nau'in ƙararrawar iskar gas mai ƙonewa shine ɗaya ko biyu, yayin da nau'in ƙararrawar iskar oxygen don babba ko ƙananan iyaka) zai nuna a gaban naúrar, fitilun baya, LED. walƙiya kuma tare da rawar jiki, alamar lasifikar ta ɓace slash, wanda aka nuna a FIG.3.

Fig.3 Alamar Interface

1. Nau'in nunin iskar gas guda ɗaya:

Nuna: nau'in gas, matsayi na ƙararrawa, lokaci, ƙimar ƙararrawar liba ta farko (ƙararrawa mafi girma), ƙimar ƙararrawa matakin na biyu (ƙananan ƙararrawa), kewayo, ƙimar maida iskar gas na yanzu, naúrar.

Ƙarƙashin ƙimar maida hankali na yanzu akwai halayen "dawowa" na gaba "na gaba", wanda ke wakiltar maɓallan ayyuka masu dacewa a ƙasa. Danna maɓallin "na gaba" da ke ƙasa (wato hagu), allon nuni yana nuna wani alamar iskar gas, kuma latsa hagu na haɗin gas hudu zai nuna sake zagayowar.

Fig.4 Carbon monoxide

FIG.5 Hydrogen sulfide

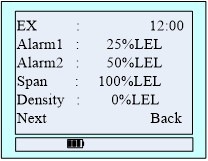

FIG.6 Gas mai ƙonewa

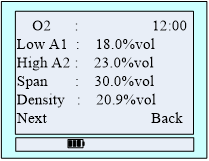

FIG. 7 Oxygen

Panel nunin ƙararrawa ɗaya wanda aka nuna a hoto 8, 9:

Lokacin da ɗaya daga cikin ƙararrawar iskar gas, "na gaba" ya zama "mai shiru", danna maɓallin busa don zama bebe, musanya na'urar zuwa ainihin font bayan "na gaba."

FIG.8 Matsayin ƙararrawar oxygen

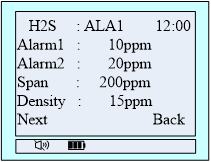

FIG.9 Halin ƙararrawar hydrogen sulfide

2.3 Bayanin Menu

Don shigar da menu, dole ne ka riƙe hagu da farko sannan ka danna dama, saki maɓallin hagu, duk abin da ke dubawa.

Menu yana nunawa a FIG. 10:

FIG.10 babban menu

Alamar tana nufin aikin da aka zaɓa na yanzu, danna hagu zaɓi wasu ayyuka, sannan danna maɓallin dama don shigar da aikin.

Bayanin aiki:

● Saita lokaci: saita lokaci.

● Rufe: rufe kayan aiki

● Shagon ƙararrawa: Duba rikodin ƙararrawa

● Saita bayanan ƙararrawa: Saita ƙimar ƙararrawa, ƙarancin ƙararrawa da ƙimar ƙararrawa mai girma

● Kayan aiki cal: gyare-gyaren sifili da kayan daidaitawa

Baya: baya don gano nau'ikan iskar gas iri huɗu.

2.3.1 Saita lokaci

A cikin FIG.10, danna dama kuma shigar da menu na saitin, wanda aka nuna a FIG.11:

FIG.11 menu na saitin lokaci

Alamar tana nufin lokacin daidaitawa, danna maɓallin dama don zaɓar aikin, wanda aka nuna a FIG. 12, sannan danna maɓallin hagu don canza bayanan. Danna maɓallin Hagu don zaɓar wani aikin daidaitawa lokaci.

Fig.12Ka'ida lokaci

Bayanin Aiki:

● Shekara: saita iyaka 19 zuwa 29.

● Watan: kewayon saiti 01 zuwa 12.

● Rana: kewayon saiti yana daga 01 zuwa 31.

● Sa'a: kewayon saiti 00 zuwa 23.

● Minti: kewayon saiti 00 zuwa 59.

Komawa zuwa babban menu.

2.3.2 Rufewa

A cikin babban menu, danna maɓallin hagu don zaɓar aikin 'kashe', sannan danna maɓallin dama don rufewa.

Zai iya dogon danna maɓallin dama na daƙiƙa 3 ko fiye a kashe.

2.3.3 Shagon ƙararrawa

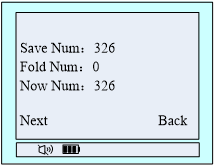

A cikin babban menu, zaɓi aikin 'record' a hagu, sannan danna dama don shigar da menu na rikodi, kamar yadda aka nuna a adadi 14.

● Ajiye lamba: jimlar adadin rikodin ƙararrawa na ajiyar kayan ajiya.

● Lamba Lamba: adadin kayan ajiyar bayanai idan ya fi girma fiye da jimlar ƙwaƙwalwar ajiya zai fara dawowa daga ɗaukar bayanai na farko, in ji ɗaukar hoto na lokutan.

Yanzu Lamba: lambar ma'auni na yanzu, wanda aka nuna an ajiye shi zuwa Lamba 326.

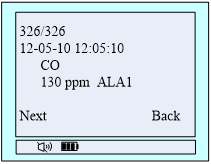

Hoto na 14 Rikodin ƙararrawa duba Hoto 15 takamaiman ƙirar tambaya ta rikodin

Don nuna sabon rikodin, duba rikodin a hagu, danna maɓallin dama don komawa zuwa babban menu, kamar yadda aka nuna a adadi 14.

2.3.4 Saita bayanan ƙararrawa

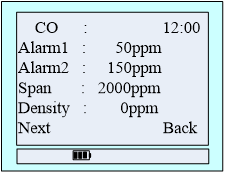

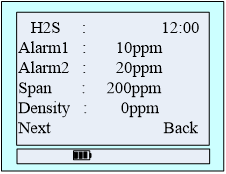

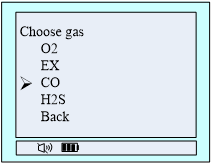

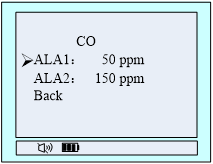

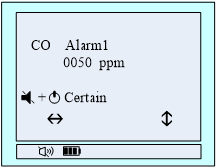

A cikin babban menu, danna maɓallin hagu don zaɓar aikin 'Set alarmdata', sannan danna maɓallin dama don shigar da ƙararrawar zaɓin zaɓin iskar gas, kamar yadda aka nuna a adadi 17. Danna maɓallin hagu don zaɓar nau'in iskar gas don saitawa. Ƙimar ƙararrawa, danna dama don shiga cikin zaɓin ƙirar ƙimar ƙararrawar gas. Anan a cikin yanayin carbon monoxide.

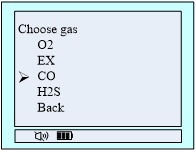

FIG. 16 Zabi gas

FIG. 17 Saitin bayanan ƙararrawa

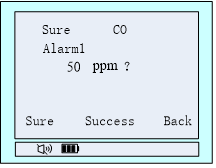

A cikin hoto na 17, danna maballin hagu don zaɓar saitin ƙimar ƙimar ƙararrawar carbon monoxide, sannan danna maɓallin dama don shigar da menu na saitunan, kamar yadda aka nuna a hoto na 18, sannan danna maɓallin hagu don canza bayanan. danna maballin dama yana walƙiya ta hanyar ƙimar lamba da ɗaya, game da saitunan maɓalli da ake buƙata, bayan saita latsa kuma ka riƙe maɓallin danna dama na hagu, shigar da ƙimar ƙararrawa don tabbatar da ƙirar lamba, sannan danna maɓallin hagu, saita bayan kunnawa. nasarar tsakiyar matsayi na kasan nunin allo, da kuma 'nasara' nasihun' sun kasa', kamar yadda aka nuna a adadi 19.

Lura: saita ƙimar ƙararrawa dole ne ya zama ƙasa da ƙimar tsoho (ƙananan iyakar oxygen dole ne ya fi ƙimar tsoho), in ba haka ba zai gaza.

FIG.18 tabbatar da ƙimar ƙararrawa

Fig.19An saita cikin nasara

2.3.5 Daidaita Kayan aiki

Lura: Ana kunna na'urar ne kawai bayan farawa na sifili calibration da calibration na gas, lokacin da na'urar ke gyarawa, dole ne gyara ya zama sifili, sannan daidaitawar iska.

Kamar yadda aka saita lokaci guda, fara kawo babban menu, sannan danna dama cikin menu na "System Settings".

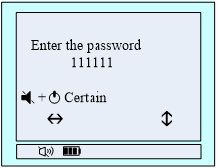

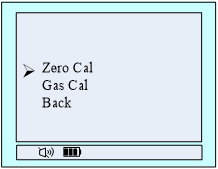

Sifili calibration

Mataki 1: Matsayin menu na 'System Settings' wanda maɓallin kibiya ya nuna shine don zaɓar aikin. Latsa maɓallin hagu don zaɓar 'daidaita kayan aiki' abubuwan fasalin. Sannan maɓallin dama don shigar da kalmar shigar da kalmar wucewa menu na calibration, wanda aka nuna a hoto na 18. Bisa ga jeri na ƙarshe na gumakan suna nuna wurin dubawa, maɓallin hagu don canza raƙuman bayanai, maɓallin dama zuwa da lambobi mai walƙiya a halin yanzu. Shigar da kalmar wucewa 111111 ta hanyar haɗin maɓallan biyu. Sannan ka riƙe maɓallin hagu, maɓalli na dama, na'ura mai ba da hanya tsakanin hanyoyin sadarwa tana jujjuya zuwa wurin zaɓin daidaitawa, kamar yadda aka nuna a hoto na 19.

FIG.20 Kalmar wucewa Shiga

FIG.21 Zaɓin daidaitawa

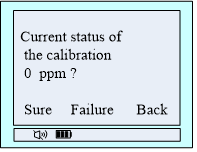

Mataki 2: Danna maɓallin hagu don zaɓar abubuwan fasalin 'zero cal', sannan danna menu na dama don shigar da sifilin calibration, zaɓi iskar gas da aka nuna a hoto na 21, bayan tantance gas ɗin yanzu shine 0ppm, danna maɓallin hagu don tabbatarwa, bayan haka. calibration na ya yi nasara, layin ƙasa a tsakiya zai nuna 'calibration of nasara' akasin haka wanda aka nuna kamar yadda aka nuna a 'calibration of Failed', wanda aka nuna a hoto na 22.

FIG.21 Zabi gas

FIG.22 Zaɓin daidaitawa

Mataki 3: Bayan sifili calibration ya cika, danna dama don komawa zuwa calibration na allon zaɓi, a wannan lokacin zaku iya zaɓar calibration na iskar gas, danna menu na gano matakin gano matakin matakin ɗaya, akwai kuma a cikin allon ƙirgawa, kar a danna. kowane maɓalli idan aka rage lokacin zuwa 0 fita ta atomatik daga menu, Komawa wurin gano iskar gas.

Gas calibration

Mataki 1: Bayan iskar gas ɗin ya kasance tabbataccen ƙimar nuni, shigar da babban menu, kira sama zaɓin menu na Calibration.Hanyoyin aiki na musamman kamar mataki na ɗaya na share calibration.

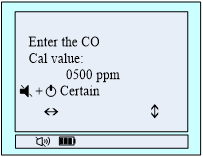

Mataki na 2: Zaɓi abubuwan fasalin 'gas calibration', danna maɓallin dama don shigar da ƙimar ƙimar Calibration, sannan saita ƙimar daidaitaccen iskar gas ta maɓallin hagu da dama, ɗauka yanzu cewa Calibration iskar gas ce ta carbon monoxide, ƙaddamar da ƙimar iskar gas ɗin Calibration. shine 500ppm, a wannan lokacin saita zuwa '0500' na iya zama. Kamar yadda aka nuna a hoto na 23.

Hoto23 Saita yawan adadin iskar gas

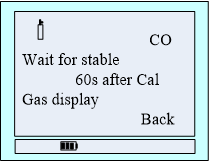

Mataki 3: Bayan saita calibration, riƙe ƙasa da maɓallin hagu da maɓallin dama, canza mu'amala zuwa madaidaicin iskar gas, kamar yadda aka nuna a cikin hoto 24, wannan ƙirar tana da ƙimar da aka gano ta yanzu.

Hoto 24 Matsalolin Daidaitawa

Lokacin da kirgawa ya tafi 10, zaku iya danna maɓallin hagu zuwa daidaitawa ta hannu, bayan 10S, gas ɗin yana daidaita atomatik, bayan Calibration ya yi nasara, ƙirar tana nuna nasarar Calibration! 'Sai akasin Nuna' Calibration ya kasa! Tsarin nuni da aka nuna a hoto na 25.

Hoto 25 Sakamakon daidaitawa

Mataki na 4: Bayan Calibration ya yi nasara, ƙimar gas ɗin idan nunin bai tsaya ba, Kuna iya zaɓar 'rescaled', idan daidaitawar ta gaza, duba ƙididdigar iskar gas da saitunan daidaitawa iri ɗaya ne ko a'a. Bayan an gama daidaita iskar gas, danna dama don komawa wurin gano iskar gas.

2.4 Cajin Baturi da Kulawa

Matsayin baturi na ainihi yana nuni akan nunin, kamar yadda aka nuna a hoton da ke ƙasa.

Na al'ada

Na al'ada Na al'ada

Na al'ada Ƙananan baturi

Ƙananan baturi

Idan baturin da aka sa ya yi ƙasa, da fatan za a yi caji.

Hanyar yin caji shine kamar haka:

Yin amfani da cajar da aka keɓe, sanya ƙarshen kebul ɗin zuwa tashar caji, sannan caja zuwa cikin 220V. Lokacin caji yana kusan awa 3 zuwa 6.

2.5 Matsalolin gama gari da Magani

Table 4 matsaloli da mafita

| Al'amarin gazawa | Dalilin rashin aiki | Magani |

| Ba za a iya yin booting ba | Ƙananan baturi | Da fatan za a yi caji |

| karo | Da fatan za a tuntuɓi dilan ku ko masana'anta don gyarawa | |

| Laifin zagaye | Da fatan za a tuntuɓi dilan ku ko masana'anta don gyarawa | |

| Babu amsa akan gano gas | Laifin zagaye | Da fatan za a tuntuɓi dilan ku ko masana'anta don gyarawa |

| Nuni ba daidai ba ne | Sensors sun ƙare | Da fatan za a tuntuɓi dilan ku ko masana'anta don maye gurbin firikwensin |

| Dogon lokaci ba calibrated | Don Allah Calibration | |

| Kuskuren nuni lokaci | Baturin ya ƙare gaba ɗaya | Cajin kan lokaci kuma sake saita lokacin |

| Tsangwama mai ƙarfi na lantarki | Sake saita lokaci | |

| Babu fasalin daidaita sifili | Matsananciyar firikwensin tuƙi | Daidaita lokaci ko maye gurbin na'urori masu auna firikwensin |

1) Tabbatar da guje wa caji na dogon lokaci. Lokacin caji na iya tsawaita, kuma firikwensin na'urar na iya shafar bambance-bambance a cikin caja (ko cajin bambance-bambancen muhalli) lokacin da kayan aikin ke buɗe. A mafi yawan lokuta masu tsanani, yana iya ma bayyana kuskuren kayan aiki ko yanayin ƙararrawa.

2) Lokacin caji na yau da kullun na sa'o'i 3 zuwa 6 ko makamancin haka, gwada kada ku yi cajin kayan aikin cikin awanni shida ko fiye don kare ingantaccen rayuwar baturi.

3) Na'urar na iya yin aiki na tsawon sa'o'i 12 ko makamancin haka bayan cikar caji (sai dai yanayin ƙararrawa, saboda walƙiya lokacin ƙararrawa, girgizawa, sauti na buƙatar ƙarin ƙarfi. Lokacin aiki ya ragu zuwa 1/2 zuwa 1/3 lokacin kiyaye ƙararrawa. hali).

4) Tabbatar da guje wa amfani da kayan aiki a cikin yanayi mai lalacewa

5) Tabbatar da guje wa hulɗa da kayan aikin ruwa.

6) Ya kamata a cire haɗin kebul ɗin wutar lantarki, kuma a caji shi kowane watanni 2-3, don kare rayuwar baturi na yau da kullun lokacin da ba a amfani da shi na dogon lokaci.

7) Idan na'urar ta yi karo ko ba za a iya buɗe ta ba, za ka iya cire igiyar wutar lantarki, sannan ka toshe igiyar wutar lantarki don sauƙaƙa yanayin haɗari.

8) Tabbatar cewa alamun gas sun kasance al'ada lokacin bude kayan aiki.

9) Idan kuna buƙatar karanta rikodin ƙararrawa, mafi kyawun shigar da menu zuwa daidaitaccen lokaci kafin farawa bai kammala ba don hana rikicewa lokacin karanta bayanan.

10) Da fatan za a yi amfani da software na daidaitawa idan an buƙata, saboda kayan aikin kaɗai ba za a iya daidaita shi ba.

4.1 Serial sadarwa igiyoyi

Haɗin yana kamar haka. The gas Detector+ tsawo na USB + kwamfuta

Connection: dayan ƙarshen serial tsawo na USB yana haɗa kwamfutar, mini USB ya haɗa kayan aiki.

Connection: kebul na USB yana haɗa zuwa kwamfuta, micro USB an haɗa shi da Detector.

Da fatan za a yi aiki ta hanyar haɗa tare da umarni a CD.

4.2 Saita Sigar

Don saita sigogi, da fatan za a yi amfani da software na daidaitawar injin gano iskar gas mai dacewa.

Lokacin saita sigogi, gunkin USB zai bayyana a nunin. Wurin gunkin USB yana bayyana bisa ga nuni. FIG.26 shine ɗayan toshe kebul na kebul lokacin saita sigogi:

Fig.26 Interface na Saita Sigogi

Alamar USB tana walƙiya lokacin da muka saita software a cikin "ainihin nuni" da "gas calibration" allon; a cikin "Parameter Settings", kawai danna maɓallin "karanta sigogi" da "saitin sigogi", kayan aikin na iya bayyana alamar USB.

4.3 Duba rikodin ƙararrawa

Ana nuna dubawa a ƙasa.

Bayan karanta sakamakon, nunin yana komawa zuwa nau'ikan nunin iskar gas iri huɗu, idan kuna buƙatar dakatar da karanta ƙimar rikodin ƙararrawar, danna maɓallin "baya" a ƙasa.

FIG.27 Karatun rikodin dubawa